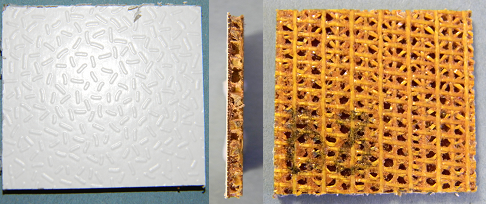

R-TECH Materials received an enquiry from a company that wanted to reverse engineer an aircraft interior panel made by a competitor, in order to replicate it. Several pieces of the panel were sent to R-TECH for analysis. Initial imaging revealed the structure that can be seen in the header image, which shows a panel of sandwich construction. Images of the received panel section can be seen below:

Figure 1: Front, Side and Rear Orientations of Aircraft Interior Panel

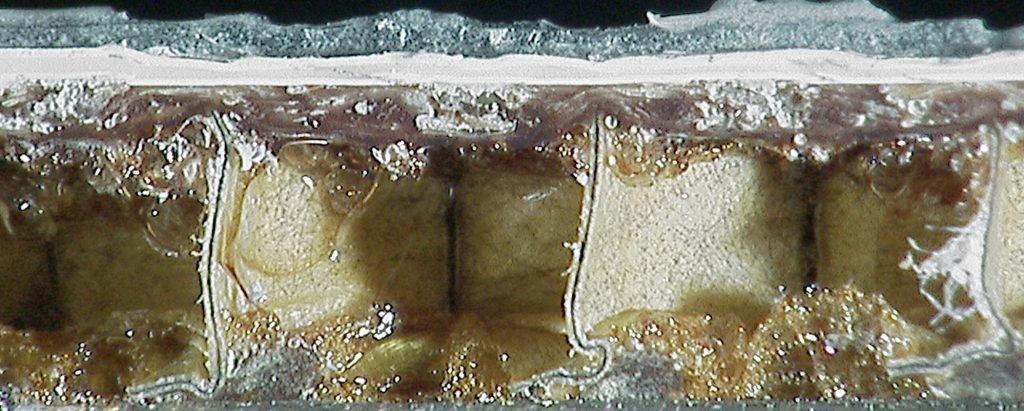

Figure 2: Macroscopic image of panel

The density of the panel was measured prior to determining any further information about the panel. The layers of the laminate panel were separated using a scalpel in order to determine the weaves of each layer. One the weaves were determined, each layer was then analysed via Fourier Transform Infrared Spectroscopy in order to determine the resin used, which indicated that the resin was a phenolic. SEM imaging was also used to to give information with regards to the makeup of the decorative coating. One of the panels was then used to determine the burn behaviour of the panel, which once removed from a bunsen flame immediately extinguished itself and remained structurally sound.

Finally the panel was placed into a muffle furnace, which allowed the number of layers and the weaves of each of the individual laminate layers to be determined, long with revealing that the core material was a paper honeycomb.