Advanced Analytical Testing Services at R-TECH Materials

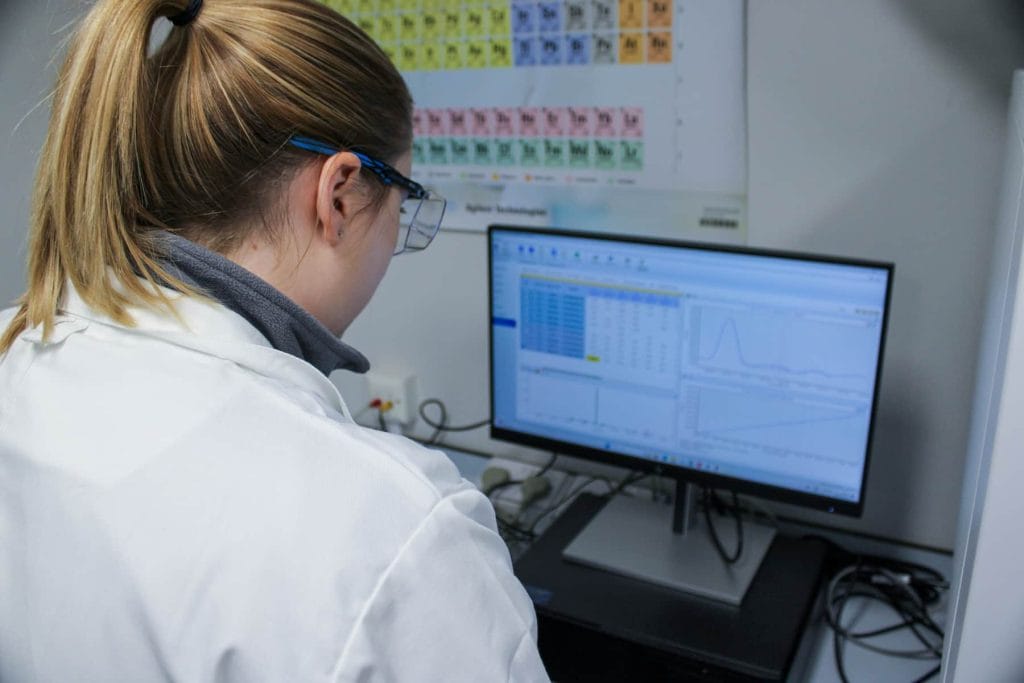

At R-TECH Materials, we are proud to announce the expansion of our analytical capabilities, now enhanced by the addition of Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), microwave digestion, and other state-of-the-art techniques. These advancements significantly enhance our ability to deliver precise and reliable metal analysis, ensuring the highest standards of quality control and compliance across a wide range of industries.

This extends further the expertise R-TECH Materials can offer to its customer.

ICP-OES: Cutting-Edge Metal Analysis

ICP-OES is a leading analytical technique that allows for the accurate determination of elemental concentrations in metal alloys, both in solid and liquid samples. By using high-temperature plasma to excite metal atoms, the emitted light is measured, enabling the quantification of elements with exceptional precision. The key benefits of our ICP-OES testing include:

- Multi-element analysis in a single test: Detects a broad range of elements simultaneously, streamlining testing.

- Wide detection range: Capable of detecting metals from trace levels to bulk quantities.

- Versatility in sample forms: We can analyze various metal forms, including powders, castings, and wrought alloys.

- Rapid analysis: Efficiently assesses a wide range of alloys such as Brass, Bronze, Carbon Steel, Cast Iron, Cobalt, Copper, Gun Metal, Nickel, and Stainless Steel.

Microwave Digestion for Advanced Sample Preparation

To complement our ICP-OES testing, we utilize microwave digestion, an advanced sample preparation technique. This method uses controlled pressure and temperature to effectively dissolve challenging sample types, ensuring that even the most complex samples can be accurately analyzed. This ensures more consistent and reliable results in metal testing.

Combustion and Fusion Analysis for Critical Elements

In addition to ICP-OES and microwave digestion, R-TECH Materials offers combustion and fusion analysis for precise determination of key elements in materials. This includes:

- Carbon (C) and Sulfur (S): Accurately measured using combustion analysis.

- Nitrogen (N) and Oxygen (O): Determined via fusion analysis.

These tests are essential for quality control and regulatory compliance in industries that demand high standards for material composition. Our LECO analyzers provide particularly accurate results for carbon content, especially in materials like cast iron and high-carbon steels, ensuring optimal performance and compliance.

Industry-Specific Testing Solutions

- Carbon Steel

- Cast Iron: With the ability to analyze carbon content via combustion analysis or through calibration adjustments on the LECO analyzer for high carbon content.

- Cobalt Alloys

- Copper Alloys & Brasses

- Nickel Alloys

- Stainless Steels

Please note that, at this time, we do not plan to offer analysis for Aluminum or Titanium alloys, but we are continuously reviewing our capabilities to meet the evolving needs of industry.

Delivering Precision, Reliability, and Efficiency

With these new capabilities, R-TECH Materials is committed to delivering unparalleled precision and reliability in metal testing. Our clients benefit from:

- Enhanced accuracy in even the most challenging samples.

- Faster turnaround times due to streamlined sample preparation and testing processes.

- Expert support from a skilled team that tailors solutions to your specific project requirements.