Field Replication Metallography

The majority of our materials investigations involve removing components from service and their subsequent destructive testing. But what do we do when a component or piece of plant cannot be removed?

Metal components, structures and systems can be subject to some of the harshest safety critical operating conditions and environments. Depending upon the application, the underlying microstructure can be subject to a variety of degradation mechanisms that can affect the overall mechanical performance. Having the opportunity to examine actual metal samples within a laboratory can provide detailed insight into any degradation, and the possible impact upon the functionality. However, taking actual samples from an operational location is often not practical and could impair the integrity of the subject matter. The alternative to this is to replicate the preparation techniques used within a laboratory, in-situ directly upon the subject component. Utilising specialist replication material, a specialist technician is able to take what is in essence a carbon copy of the underlying microstructure. This essentially non-destructive technique is referred to as field metallographic replication. The application of this technique can facilitate the identification of a number of degradation mechanisms enabling their management, thus minimising unplanned outages and avoiding catastrophic failures. The results of this technique can be used for a wide number of purposes, including but not limited to:

- Assessment of any high temperature creep damage.

- Assessment of graphitisation in carbon and low alloy steels.

- Determination of crack morphology and path in order to support the management of defects and failure investigations.

- Assessment of sigma phase embrittlement and sensitisation in stainless steels.

- Fire damage assessment.

- Assessment of weld quality.

- Assessment of weld failure mechanisms.

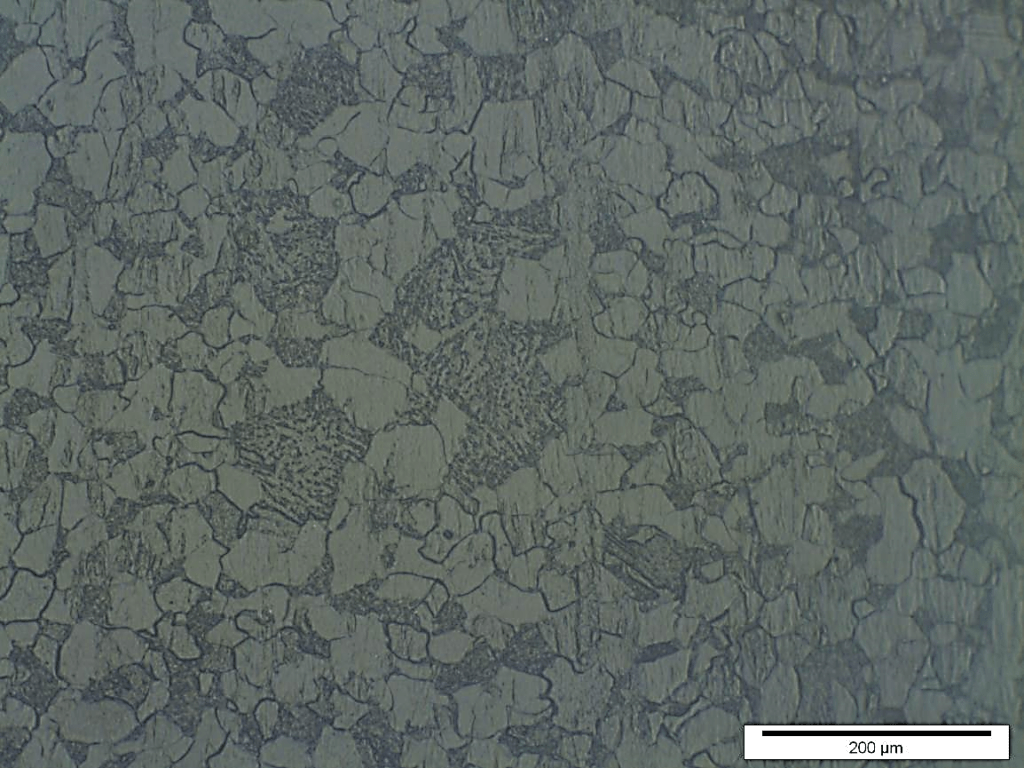

- Verification of a metals microstructure in-situ (Figure 1).

Figure 1: Replica of a low alloy steel

Field metallurgical replication results are highly dependent upon the skill set of the technician and the selection of a suitable etchant. It is possible to damage the metal substrate without having suitable training and expertise. R-TECH Materials have several highly trained field metallurgical replication technicians who have experience in the execution of jobs assessing carbon steels, low alloy steels, stainless steels & nickel base alloys on a global basis. Interpretation of field metallurgical replicas is undertaken by our skilled team of Chartered metallurgists. A wide variety of standards can be used to assess the results against, as required.

As requested, R-TECH Materials can also offer in field interpretation of replicas in order to support outage schedules. Field metallographic replication is an essential tool for ensuring plant operation continuity and safety of operation personnel and the public.

Field metallographic replication is complimented by the other on-site services offered by R-TECH Materials:

- Positive Materials Identification (XRF)

- Hardness Testing

- Ultrasonic Thickness Gauging

To find out how R-TECH Materials can support your Total Productive Maintenance (TPM) / Planned Preventative Maintenance (PPM) inspection regime please feel free to contact us.