Permanent Slip

One of the key performance characteristics for a mechanical coupler is the permanent extension (slip) across the joint when loaded to a specified stress, which is normally a specified proportion of the yield stress. This is important, since the extension across the joint in service will cause the surrounding concrete to crack. Design codes have limitations on crack widths in order to maintain adequate durability by protecting the reinforcement against corrosion and fire. Generally, the permanent extension is measured after stressing the joint to 0.6 or 0.65 fy, where fy is the characteristic yield stress of the reinforcing bar specified.

R-Tech Materials are able to offer UKAS accredited testing of permanent slip against BS 8597 and ISO 15835-2.

The method historically used in the UK involved stressing the joint to 0.6 fy.

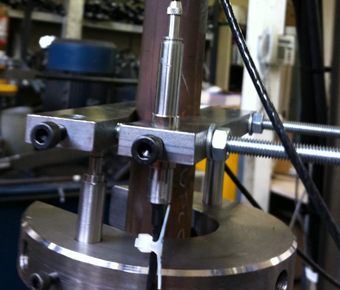

The measurement of permanent extension requires at least a dual averaging extensometer arrangement. Because of the way they are made, mechanical splices tend to show some degree of misalignment, and hence the dual averaging extensometer arrangement is critical to achieving an accurate result. The gauge length of the extensometer is often specified to be within certain limits related to the length of the coupler and the diameter of the bar in the joint. R-Tech Materials has variable length extensometers capable of handling most common couplers, including transitional and positional couplers.

For customers requiring testing of more complex mechanical couplers, R-Tech Materials has the capability of measuring the permanent extension across different joints of a mechanical coupler. In this case the measurement of extension is by means of Linear Variable Differential Transformer (LVDTs), again in a dual averaging arrangement. This technique has been used to help manufacturers identify the extension in different parts of their joints, which has assisted in product development.