Welding & Mesh Products

The use of welded prefabrication of reinforcing steels has increased significantly in recent years as the benefits of faster site construction times have been appreciated by designers and contractors. Although most rebar welding is off-site prefabrication, there is also a significant volume of on-site welding conducted. Welded fabrications may be for standard items such as beams, pile cages or roll mats, or for more bespoke products such as the Superlatch lifting system.

High yield reinforcing steel is a relatively highly alloyed structural steel, and the properties of the welded fabrication are strongly dependent on the precise control of the welding conditions. This has been recognised by the publication of BS 8548:2017, which links with ISO 17660, Parts 1 and 2. Together these documents provide a comprehensive scheme for the control of welding of reinforcing steels, in line with UK practice. UK CARES have also published new appendices to their SRC product certification scheme, which link to these standards for locational welds (Appendix 11) and structural welds (Appendix 12). A brief description of how these documents fit together can be found in the following white paper.

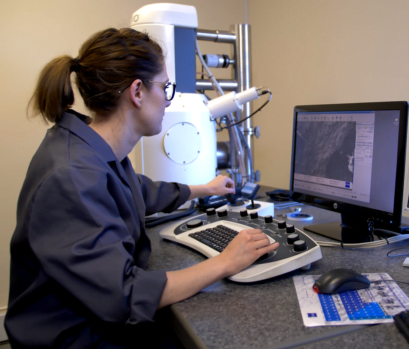

R-TECH Materials have experienced, qualified IIW/EWF Welding Technologists who can advise and assist fabricators to enable them to meet the requirements of the new standards. Our services include:

- Acting as a responsible Welding Coordinator on a contract basis

- Training of Company Welding Coordinators

- Testing of welds for weld procedure and welder qualification

Welding Procedures and QMS

Because of the potential of inappropriate welding conditions to compromise the integrity of reinforcing steels, it is vitally important that welding is conducted under a Quality Management System, which meets the requirements of BS 3834-2, and provides consistent quality of welds meeting the required technical standards. Within even the most basic welding arrangements, there will be a multiplicity of standards which apply covering for example raw materials, welding processes, consumables, quality systems, test requirements, qualification requirements. This can be a very confusing landscape of requirements, and not every fabricator can afford to have a full-time Welding Specialist to manage these tasks. R-Tech Materials can assist in developing Quality management Systems for welding which meet the requirements of the relevant international standards, and the CARES SRC Appendices. Our staff can also act as Responsible Welding Coordinators (as defined in BS 8548) under contract, in which we take on the responsibility for certain parts of the QMS alongside your own Company Welding Coordinators.

Welding Procedures & QMS

Because of the potential of inappropriate welding conditions to compromise the integrity of reinforcing steels, it is vitally important that welding is conducted under a Quality Management System, which meets the requirements of BS 3834-2, and provides consistent quality of welds meeting the required technical standards. Within even the most basic welding arrangements, there will be a multiplicity of standards which apply covering for example raw materials, welding processes, consumables, quality systems, test requirements, qualification requirements. This can be a very confusing landscape of requirements, and not every fabricator can afford to have a full-time Welding Specialist to manage these tasks. R-Tech Materials can assist in developing Quality management Systems for welding which meet the requirements of the relevant international standards, and the CARES SRC Appendices. Our staff can also act as Responsible Welding Coordinators (as defined in BS 8548) under contract, in which we take on the responsibility for certain parts of the QMS alongside your own Company Welding Coordinators.

Responsible Welding Co-ordinators

Cares Scheme Appendix 11 and 12 require all rebar fabricators to appoint a Reponsible Welding Co-ordinator to act on their behalf. This co-ordinator is responsible for ensuring that the QMS and weld procedures are maintained to the standards of the specification and……

R-TECH Materials can provide an IIW/EWF qualified Welding Technologist who can act as a Responsible Welding Coordinator on a contract basis.

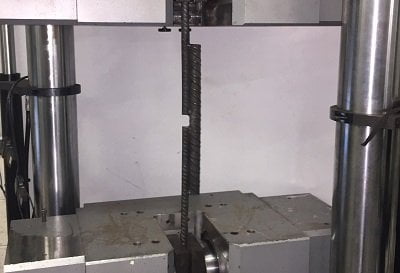

Mechanical Testing

R-TECH’s steel testing laboratory is the leading provider of weld testing to the reinforcing steel industry. The laboratory is UKAS accredited for all tests required by BS 8548, ISO 17660 and CARES SRC Appendices 11 and 12.

Standard tests include the following:

- Tensile tests

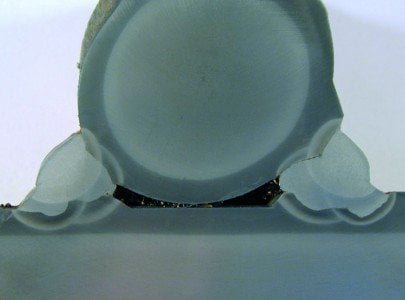

- Macro examination

- Weld shear tests

- Hardness tests

- Bend tests

Training for Company Welding Co-ordinators

R-TECH Materials have recently developed a 4 day training course for company welding co-ordinators specifically designed to help weld fabricators meet the requirements of CARES Appendix 11 & 12. This four-day course held periodically in South Wales, includes presentations on the core elements of the welding co-ordinator role, demonstrations of the necessary testing for welding approval and a short multiple choice examination. Each successful participant will receive a recognised certificate. More info here.

Welder Approval

R-TECH Materials offers all the tests on welded reinforcing steels required for the approval of weld procedures and welder qualifications tests. In addition to test reports, approval certificates are issued showing the range of approval according to international standards.

In some cases, additional support can be given to help welders meet their approval requirements where this is proving difficult to attain.

Failure Investigation

Where welds have failed in service or where welding problems have been identified, our consultancy team are highly experienced in investigating the cause of the weld failure/problem and can act as expert witness in the case of welding related disputes or legal cases. More info here.