R-TECH Materials invests in Zwick Roell’s latest composites testing technology

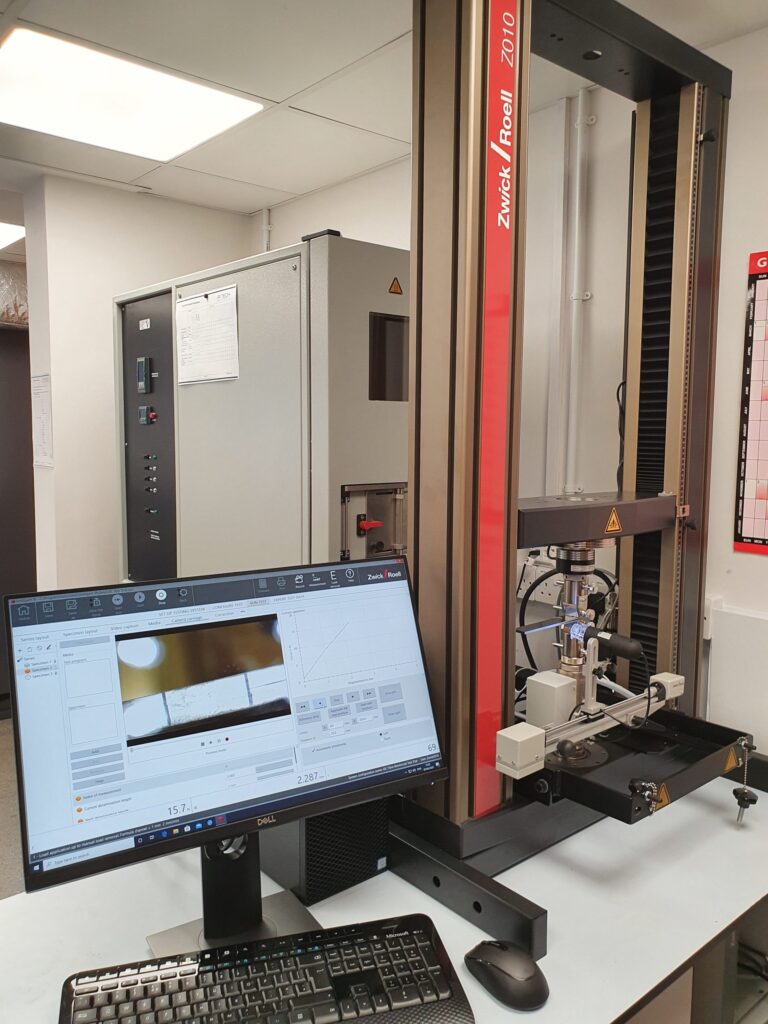

R-TECH Materials has invested in a new Zwick Roell 10 kN ALLroundLine universal testing machine for its rapidly growing polymer and composites test laboratory.

Renowned for the quality of its equipment and highly sophisticated software suite, the German-made Zwick Roell machine – which will be aligned to aerospace testing standards – will enable R-TECH to carry out more complex testing to fulfil the increasingly demanding requirements of its customers. The machine operates with the latest Zwick Roell testXpert III control software package which provides a comprehensive range of modules, to facilitate tensile, compression, flexure, shear, tear growth, adhesion, peel and cyclic testing, at loads from 1N to 10 kN. Embedded programs are available to meet the requirements of more than 600 standard tests and can also be customised to cater for bespoke requirements.

The Zwick Roell machine, is equipped with a thermal chamber supplied by Severn Thermal Solutions and can perform tests in the temperature range -70°C to +250°C. R-TECH can also perform liquid, humidity or temperature pre-conditioning of samples, which is an essential requirement for the aerospace sector. The new investment also incorporates the latest Zwick Roell state-of-the-art camera system for fracture toughness testing. This system enables accurate tracking of the crack propagation and allows the test sequence to be replayed post-test to ensure accurate detection of the crack front, making it the most accurate and repeatable system in the U.K. testing market. R-TECH have also invested in fixturing that will allow them to carry out V-notched rail shear testing.

The Zwick Roell machine, is equipped with a thermal chamber supplied by Severn Thermal Solutions and can perform tests in the temperature range -70°C to +250°C. R-TECH can also perform liquid, humidity or temperature pre-conditioning of samples, which is an essential requirement for the aerospace sector. The new investment also incorporates the latest Zwick Roell state-of-the-art camera system for fracture toughness testing. This system enables accurate tracking of the crack propagation and allows the test sequence to be replayed post-test to ensure accurate detection of the crack front, making it the most accurate and repeatable system in the U.K. testing market. R-TECH have also invested in fixturing that will allow them to carry out V-notched rail shear testing.

Dr Geraint Harvard, R-TECH’s Composite Manager, said; “We are delighted with our new Zwick Roell machine. It has become apparent that there is a growing demand for fracture toughness testing within the composites industry, partly due to the publication of ISO 20144, the standard qualification plan for composite materials, which includes fracture toughness testing. We decided that it was important to position ourselves with the most accurate and repeatable system on the market for all fracture toughness modes required. Our continued investment in state-of-the-art equipment and the ongoing development of our team of highly qualified engineers, materials scientists, and chemists has helped us forge our reputation as one of the U.K.’s fastest-growing composite testing laboratories.”

R-TECH is accredited by UKAS and Nadcap to perform testing to ISO and ASTM standards under controlled temperature and humidity conditions. Standard tests include lap shear, in-plane shear, climbing drum peel, shore hardness, compression of core materials and shear properties of sandwich panels. As well as a full suite of static testing, fatigue testing (in tension or in bending) at loads of up to 100 kN can also be accommodated. R-TECH’s skilled technical staff can prepare laminates and machine samples in-house as required.

R-TECH also offers its customers bespoke testing thanks to its combination of state-of-the-art biaxial extensometry with strain gauging capabilities and in-house workshop facilities, which means it can design and manufacture rigs to adapt its test equipment to clients’ requirements.