#EpicFail – Sensitisation

Stainless steels acquire their “stainless” characteristic when the chromium content exceeds 10.5%. Above this level, a protective chromium oxide layer is formed, known as a passive film, which provides the material with its superior corrosion resistance. However, if the material is heat treated incorrectly during manufacture or welding or exposed to elevated temperatures during service, microstructural changes can occur which effectively means that the material is no longer a stainless steel in a localised area. Exposure to temperatures in the range 370-815ᵒC allows the precipitation of chromium rich carbides/nitrides along the grain boundaries, a phenomenon known as sensitisation. These precipitates are rich in chromium and deplete the area directly adjacent to the boundary of chromium, thereby increasing the likelihood of localised corrosion in the form of stress corrosion cracking, intergranular attack and pitting in a corrosive environment.

Sensitisation is a common occurrence in the austenitic 300 series type, though the phenomenon can also occur in duplex, ferritic, martensitic and precipitation hardened stainless steel grades.

Chromium carbide precipitation can occur during exposure to high operating temperatures. This is not deemed to be an issue if the operating temperatures remains above the dew point temperature. However, in the presence of moisture and air, intergranular attack can occur due to the localised depletion of chromium adjacent to the grain boundaries. For materials with a metal sulphide scale from exposure to sulphur containing species during operation, the scale may react with air and moisture to form polythionic acid. This in combination with a stress, residual or applied, can lead to a phenomenon known as polythionic stress corrosion cracking.

Chromium carbide precipitation can also occur by slow cooling from elevated temperature such as solution annealing during manufacture or welding. The phenomenon associated with welding is commonly termed weld decay where the heat affected zone is locally sensitised and thus susceptible to intergranular attack.

How can sensitisation be prevented?

- Low carbon variants (i.e. 304L, 316L) and stabilised grades alloyed with titanium (321) or niobium (347) can be used to delay the onset of sensitisation and are commonly used where welds are necessary. These additions are stronger carbide formers than chromium and tie up the carbon so that chromium carbides are not formed. Titanium or niobium additions also reduce the solubility of carbon in austenite resulting in MC type carbides, where M represents titanium or niobium.

- Fast cooling rates during heat treatment and welding are necessary to reduce the likelihood of sensitisation.

- The heat treatment applied during manufacture or welding can be verified using a simple corrosion test. ASTM A262 details various practices that can be performed to verify a material’s corrosion performance depending on the chemical composition and application of the component.

- For materials exposed to elevated temperature during service, although the low carbon and stabilised grades reduce susceptibility to sensitisation at short exposure times to elevated temperature, chromium rich carbides still precipitate after long-term ageing. Therefore, careful management during start-up/shut-down would need to be implemented to minimise the risk of exposure to moisture. Recommended practices include:

- Flushing the equipment during or immediately after shutdown with an alkaline solution or soda ash, which helps neutralize any polythionic acids formed due to exposure to air and moisture; and

- Purging the system with dry nitrogen or a nitrogen/ammonia mixture during shutdown to prevent air ingress and inhibit the formation of polythionic acids. For detailed procedures, refer to the guidelines outlined in NACE SP0170.

- Replication metallography can be performed to determine the presence of sensitisation without having to remove the component from site.

Real-life case study

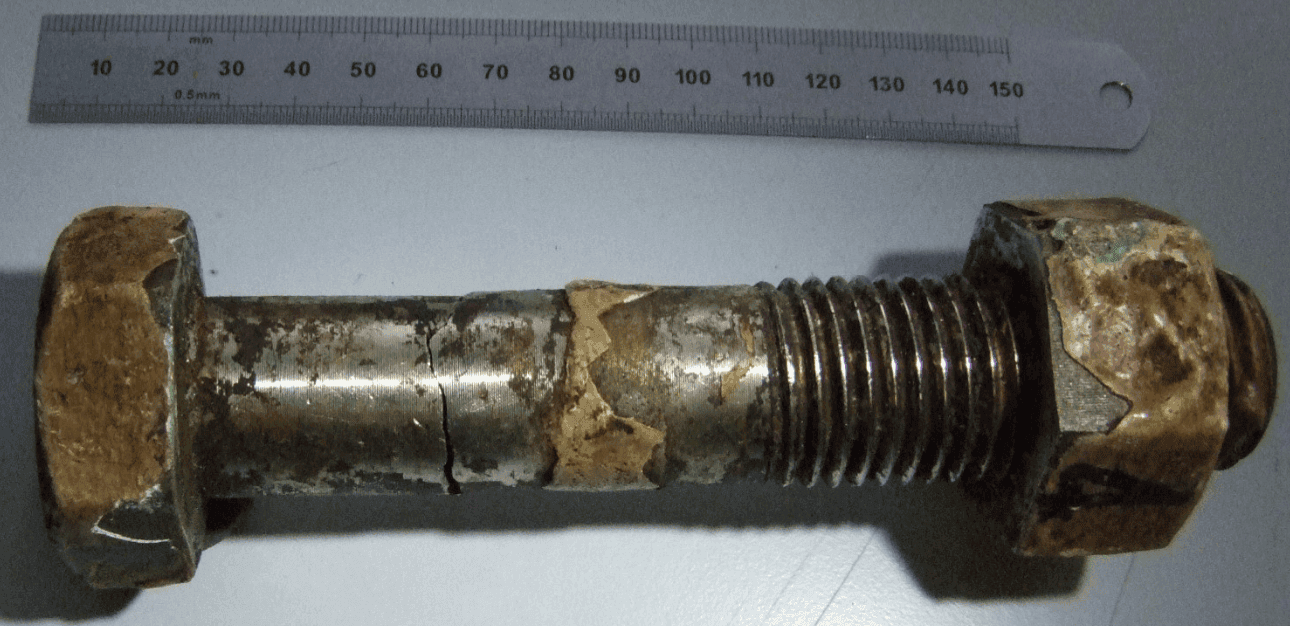

The failure of multiple stainless steel bolts, manufactured from grade 304, had led to an oil leak from the main cargo line of an oil tanker. The fracture surface of the bolts was associated with a corrosion deposit and an intergranular fracture morphology, indicating a brittle fracture.

Fractured stainless steel bolt

Brittle fracture surface associated with a corrosion deposit.

Intergranular fracture.

Examination of a section taken through the fracture surface revealed extensive intergranular branched cracking throughout the bolt. In some instances, entire grains were missing from the section. These cracks were associated with corrosion product which was found to consist of iron sulphide. Examination in the etched condition revealed chromium carbides along the austenite grain boundaries.

Intergranular cracking throughout the diameter of the bolt.

Intergranular cracking throughout the diameter of the bolt.

Austenite grains with chromium carbides at the boundaries (sensitisation).

The morphology of the cracking and the presence of sensitised austenite grains indicated that the failure was attributable to Polythionic Acid Stress Corrosion Cracking (PASCC). This phenomenon is due to the formation of sulphide scales in the presence of sulphur compounds which then react with air and moisture to form sulphur acids (polythionic acid). Polythionic acid then attacks sensitised austenitic stainless steels in the chromium depleted matrix directly adjacent to the grain boundaries, producing an intergranular fracture. The stress necessary to cause cracking can be applied or residual. Sulphur is likely to have originated from the products transferred in the cargo line.

it is vital that an adequate heat treatment is applied to austenitic stainless steels during manufacture to ensure that there is no evidence of any carbide precipitation at the grain boundaries. However, this was not the case for the bolt examined and therefore the bolt had been highly susceptible to PASCC.

For more information or expert advice feel free to contact us at info@r-techmaterials.com. Our team of specialists can assist with material integrity challenges and provide support to ensure the safety and longevity of your engineering systems.